Packaging and labeling of goods is needed in import and export trade because of 2 basic reasons: Marketing and distribution of the goods. The function of marketing is, the packager provides information to the customer about the product, and promotes the product through the use of color, graphics and product quality benefits and description. The distribution function, keeps the product free from damage as it is transported and stored.

Table of Contents

- What is Optimal Packaging ?

- Fiberboard Boxes (Cardboard Boxes)

- Nailed Wooden Boxes

- Crates

- Wire-Bound Boxes and Crates

- Cleated Plywood Boxes

- Steel Drums

- Fiberboard Drums

- Multiwall Shipping Sacks

- The Need of Shipping Marks and Symbols in the Packaging and Labeling of Goods

- Palletizing Cargo for Export Shipments

- So How do we Palletize the Goods?

What is Optimal Packaging ?

If we talk about the optimal packaging, we can say it is the one that meets requirements related to service, cost, and convenience.

The package should be designed to provide the most efficient stowage of the product for transportation and storage. Good packaging affects materials handling in terms of load stability and compatibility with different means of mechanization and automation, and it satisfies warehousing needs for stack ability and efficient storage.

The cost of materials and production is of prime importance too. One has to measure warehousing, transportation, and handling costs against packaging costs and all of these against product protection and marketing effectiveness.

To sum up the main factors involved in the design of an export package are transportation handling, climate, pilferage, freight rates, durability, and, most important of all, the requirements of the consignee.

The greater number of times goods are handled or transshipped, the greater is the risk of damage or pilferage.

It is also very important to note that, the export packer must take into consideration the inherent characteristics of the cargo itself. Fragility, shape, temperature withstanding and other inherent characteristics needs to be considered of the cargo.

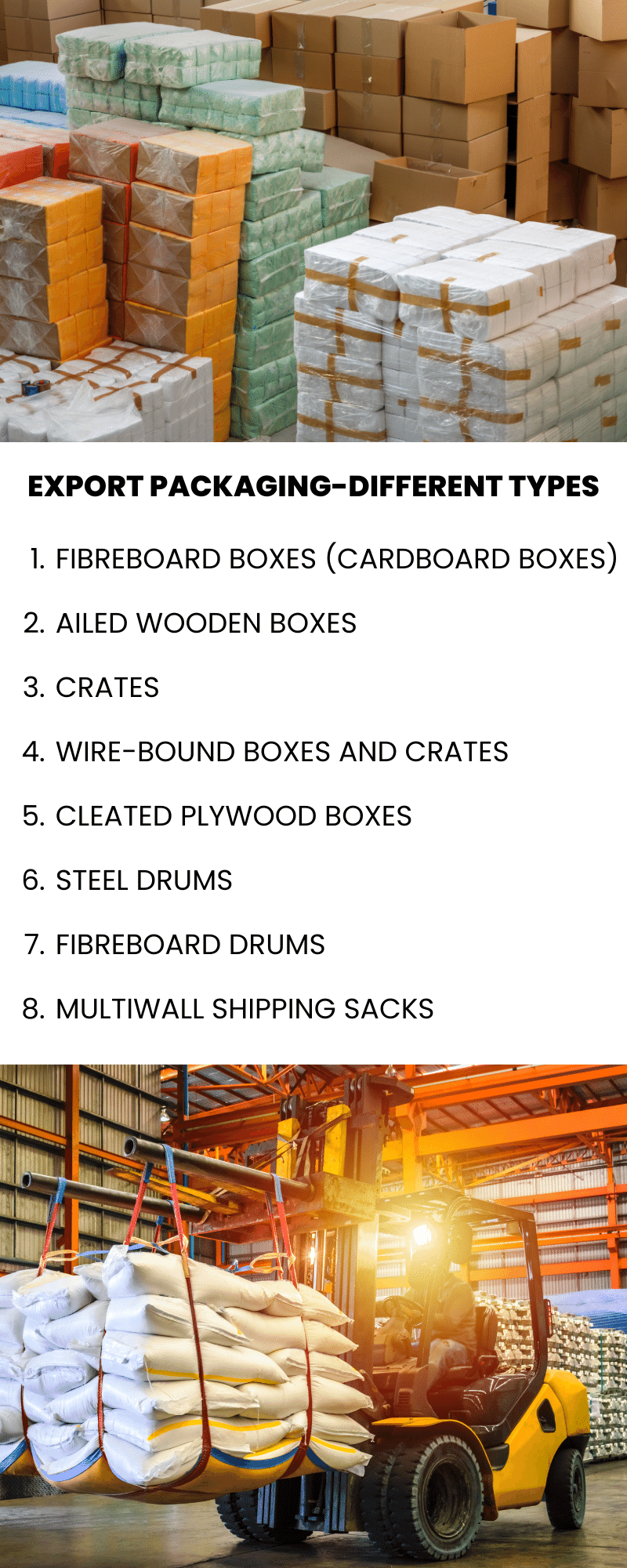

Let us see some common forms of Export Packaging

Fiberboard Boxes (Cardboard Boxes)

The most common economical packaging is cardboard boxing.

In the packaging shippers seek efficient but inexpensive and lightweight packaging.

The cardboard carton comes closest to fitting the description of the ideal packaging material; it is light in weight and of low cost but able to withstand normal transportation hazards and to protect contents against loss or damage.

Now, how does an exporter decide whether to select cardboard boxes or any other material made boxes?

The shipper should keep in mind the item’s vulnerability, as well as the handling and transportation hazards to be encountered in the export process and whether the cardboard boxes withheld that vulnerability.

The factors the shipper can take into consideration while choosing the quality of the cardboard boxes can be:

- Resistance to compression

- Resistance to puncture

- Strength of the material

- Resistance to moisture absorption

Nailed Wooden Boxes

The nailed wooden box is mostly used for transportation of moderately heavy commodities in international trade.

Let us see some of the advantages of using nailed wooden boxes:

- Its ability to support high loads

- Its ability to take difficult loads without undue distortion or breaking open

- The protection it affords the contents from damage due to puncture, breakage, or crushing

Crates

Crates are mostly used to carry small machineries. There are 2 types of crates:

- Open or skeleton crate

- Fully sheathed or closed crate

Wire-Bound Boxes and Crates

Wire-bound boxes and crates are great use for a large variety of products not affected by minor distortions of the container.

Cleated Plywood Boxes

Cleated plywood panel boxes have many uses in foreign trade. Their lightness and comparative strength particularly recommend them for air freight shipments.

Steel Drums

Steel drums are used mostly to export chemicals and liquid items. It must be taken into note that the drums are not damaged.

Fiberboard Drums

Fiberboard drums used mostly used to carry bulk-purchase food.

Multiwall Shipping Sacks

Multiwall shipping sacks or bags are used for the packaging of powdered, granular and lump materials, particularly dry chemicals.

The Need of Shipping Marks and Symbols in the Packaging and Labeling of Goods

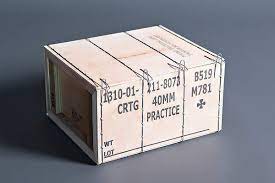

Shipping Marks and symbols are important for the identification of the goods inside the package and also for the identification of the seller and buyer of the goods. On the outside of shipping packages all the details are mentioned that enable the carrier to move it to its ultimate consignee in a safe and responsible manner.

In the packaging marks and symbols, Consignee (identification) marks and port marks showing destination and transfer points should be large, clear, and applied by stencil with waterproof ink.

They should be applied on three faces of the packing container, preferably side, ends and top.

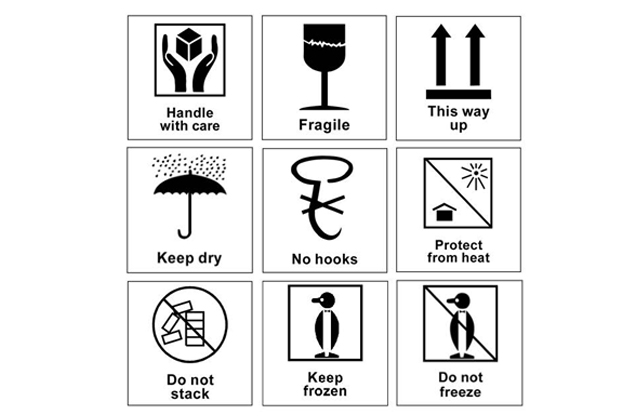

If commodities require special handling or stowage, the packaging should be so marked. Any cautionary markings must be permanent and easy to read.

For the benefit of cargo handlers, the internationally recognized pictographs depicted below should be used.

Palletizing Cargo for Export Shipments

Palletizing is the assembly of one or more packages on a pallet base and the securing of the load to it.

If we palletized packages in export shipments, the benefits we get are enormous in distribution of cargo, handling, stowage, and protection of the products and commodities.

Pallet loads have lots of advantages:

- Packing and handling cost are significantly reduced.

- The use of mechanical handling equipment, reduces the manual handling damage hazard

- Pallet and unit loads eliminate the multiple handling of individual items, further reducing possible damage from manual handling

- Reduce the opportunity for pilferage and theft and permit the early detection of tampering

- Speeds up the loading and unloading of boxcars, trailers, intermodal containers, barges, ships, and aircraft

- Facilitate the application of waterproofing protection to the load; the overwrap applied accompanies the load for the entire journey

- Reduce the incidence of lost or stray items; and facilitate checking and inventory of shipment.

So How do we Palletize the Goods?

- We should assemble the individual unit packages on the pallet base without an overhang.

- We insert spacers between the rows or layers of irregularly shaped items. Adhesives can be used between cartons in a uniform load.

- Secure the load tightly and firmly by using horizontal and vertical strapping. Plastic shrink-wrap may be used to stabilize and protect palletized loads.

- Provide stacking protection to the top of the pallet by using a lumber, plywood, or fiberboard cap.

- Loads that are susceptible to compression must be supported with vertical framing.

Good packaging makes the distribution of the products in the international trade safe to carry and prevents damage of the goods. The products getting lost is also minimized in the ports and transshipment port because of the good labeling.

From the practical scenario, it is seen that because of poor packaging the goods that are exported when reached to the importer was completely damaged and in no condition to use. For example: once we have seen an exporter exporting ripe tomatoes to Dubai. But when the tomatoes reached the destination port of Dubai, the tomatoes were not in the shape of tomatoes rather it got bruised and smashed to the point of becoming ketchup.

So, it should be kept in mind of the exporter that good and reliable packaging is a must in the international trade. No excuse and discount should be taken for the packaging.

The goal is very clear. In the international trade the end result is exporting an intact product from the exporter end to the final destination.

NO TRADE IS POSSIBLE WITH A DAMAGED PRODUCT